Wood Veneer

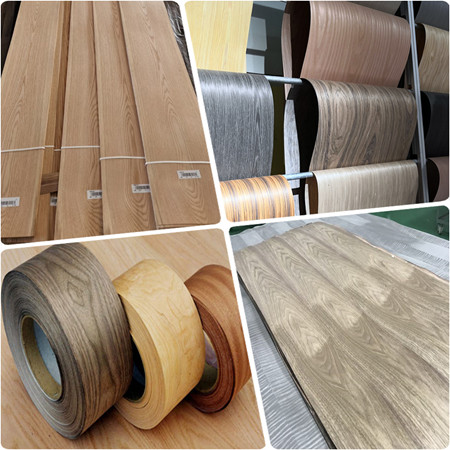

Natural wood veneer and engineered veneer are two of the most essential materials for surface decoration in modern woodworking.

We offer both veneer sheets and veneer rolls to suit a wide range of applications.

Popular wood species include White Oak, Red Oak, Walnut, Teak, Maple, Sapele, Ash, Cherry, Rosewood, Ebony, and Grey tones.

Standard veneer thicknesses are 0.25mm, 0.4mm, and 0.5mm, with custom thicknesses available upon request.

Wood veneer is widely used in furniture manufacturing, wood doors, interior design, joinery, wall paneling, and veneered plywood or MDF production, providing natural beauty and timeless appeal across industries.

Download PDF: 15 types of wood veneer

Natural Veneer & Engineered Veneer

Natural Wood Veneer

Natural wood veneer is made by thin-slicing or saw-cutting real wood directly from logs, preserving the wood’s authentic grain patterns and natural color.

The best-selling natural veneer species are American Red Oak, White Oak, Walnut, European Oak, Ash, Maple, Cherry, Teak, Beech, Ebony, and Sapele.

For those seeking more distinctive looks, we also offer exotic veneers such as Figured Maple, Bird’s Eye Maple, Rosewood, Ziricote, Burl, Crotch, and Tamo Ash.

Veneer thickness options range from ultra-thin 0.15–0.2mm sheets to standard 0.4mm and 0.5mm.

For select species like oak, walnut, and teak, we also provide thicker veneers in 1mm, 2mm, 3mm, and 5mm for high-end applications.

Engineered Wood Veneer

Engineered veneer—also name as reconstituted veneer (recon veneer) or artificial veneer—is made from fast-growing wood species such as Ayous, Basswood, and Poplar.

The main advantage is in the uniform color and grain across all sheets, ensuring a consistent appearance and easy matching throughout any project.

Alongside classic designs like Oak, Walnut, Grey, and Teak, we also offer a variety of modern and exotic patterns, including Wenge, Burl, and Rosewood.

Standard sheet size of engineered veneer is 2500 × 640 mm, with custom dimensions available upon request.

We stock 0.2 mm and 0.4 mm thicknesses as standard, and can produce up to 5 mm for specialized applications.

Download PDF: Catalog of engineered veneer

8 Best-Selling Wood Veneer

0.25mm Thin Oak Veneer

0.4mm Walnut Veneer

1mm Teak Veneer

3mm & 5mm Thick Oak Veneer

Engineered Walnut Veneer

Oak Engineered Veneer

Grey Recon Veneer

Wood Veneer Rolls

Frequently Asked Questions (FAQs)